Description

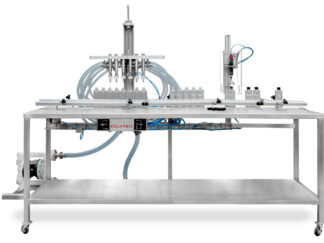

DVL Series Piston Fillers

TECHNOLOGY:

- PLC-based touchscreen HMI with intuitive controls for optimal accuracy, easy operation, and efficiency.

- DVL Series linear piston filling machines utilize vertically oriented, synchronized, electronically driven volumetric pistons.

- Electronically driven pistons allow for precise control over fill speeds and accuracy with adjustable prime and discharge speeds, as well as stroke and displacement volumes.

- Multiple pistons can be combined to achieve greater fill volumes without additional sets/sizes of pistons. For example, a single set of pistons can achieve fill volumes of 3.2 OZ – 135 OZ simply by reducing the number of fluid paths and joining pistons to work together to produce larger fills.

- DVL Series Piston Fillers are available with 4, 6, 8, 10, or 12 heads. Modular design means you can start with fewer heads and expand in the future to meet increased production needs.

USES AND/OR APPLICATIONS:

DVL Series piston fillers are ideal for packaging viscous products like oils, pastes, lotions, adhesives, liquids with particulates like salsas or salad dressings, and many other types of thicker liquid products.

- Foods (pastes, sauces, liquids with particulates)

- Oils

- Cosmetics

- Paints

- Agrochemical (with particulates)

- Chemicals (viscous)